| Wires are woven together to

create wire mesh or called wire mesh in different weave patterns, such as plain

weave and twilled weave. The most common materials used to create woven wire

cloth are metallic including carbon steel, pre-galvanized steel, aluminum,

copper/brass/bronze and stainless steel. Other materials such as Monel,

Hastelloy, Inconel, Titanium or other nickel alloys can also be woven into wire

mesh. The common finish option can be galvanizing, chrome plating, copper

plating, PVC dipping and powder coating in different colors. Carbon steel woven

wire cloth is available upto 100 mesh. |

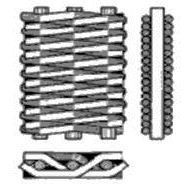

Wire cloth or wires can be

sintered together into Sintered Laminates or Sintered Felt. Space Screen and Square

Mesh in 10 mesh and coarser are typically woven from pre-crimped wires. Such

material remains stable and rigid after the crimping process. Wire cloth woven

from pre-crimped wires provides accurate openings and is woven tighter than

plain weave. Pre-crimped weaves are preferred for vibrating screens, decoration

and many other applications where sizing is critical. I.

CRIMPED STYLES Our pre-crimped woven wire

cloth is available in double weave, inter-crimp, lock-crimp, double lock-crimp,

triple shoot and flat top woven styles, and they are ideal for architectural

applications. |

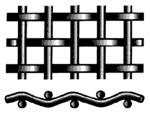

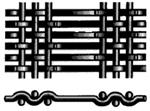

| 1. Double Crimp: The most common type. Also

referred to as "Over and Under" this weave is commonly used for screening

operations in smaller openings in comparison to the wire diameter. Used for

medium to heavy wire in relation to screen opening size. |

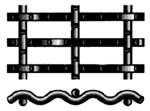

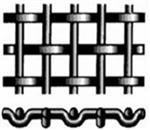

| 2. Inter Crimp: Used in coarse weaves of lighter

gauge wire to provide greater stability, tightness of weave and maximum

rigidity. Very common in mesh openings larger than 1/2"

(12.7mm). |

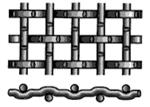

| 3. Lock Crimp: Also known as Scalping Weave.

Due to the deep crimps which lock the wires in place. It is used only in coarse

specifications to maintain the accuracy of weave throughout screen life, where

the opening is large with respect to wire diameter. |

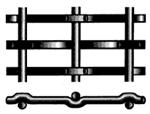

| 4. Double Lock

Crimp: Single shoot oblong openings

solve minor blinding problems for better flow. |

| 5. Triple Shoot: Long openings will keep sticky

or wet material flowing freely. Weave holds wires securely yet permits slight

vibration to keep openings clear. |

| 6. Flat Top: It usually starts at 5/8"

opening or larger providing long abrasive resistant life, since there are no

projections on top to wear and also offers least resistance to flow. It improves

material flow with a much smoother, flatter surface than other weaves, and

maintains accurate openings, and is very popular in certain architectural and

structural applications where a smooth surface on one side is

desirable. |

II. WEAVE

PATTERNS |

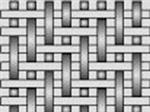

| 1. Plain Weave: The most common weave, with the

same diameter warp and weft wires woven in a simple over and under pattern. It

produces screens with the same mesh count in both directions in square openings.

Sometime the opening is in Rectangular or called Off-Count" weave. Warp and weft

wire diameters are generally the same. |

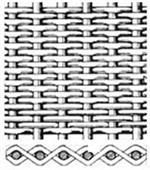

| 2. Twill Square: Each weft wire alternately

passes over two, then under two successive warp wires and each warp wire passes

alternately over two and under two successive weft wires, in a staggered

arrangement. Twill weave can be made from larger-diameter wires than would be

possible in plain square weave to obtain greater strength, density or corrosion

resistance. Twill weave is normally used to allow a heavier than standard wire

diameter in association with a given mesh. |

| 3. Plain Dutch

Weave: Also known as Plain Dutch

(Hollander) weave, woven in a plain, over and under pattern. While the warp

wires remain straight, the weft wires are plain woven to lie as close as

possible against each other in a linen weave forming a dense strong material

with small, irregular and twisting passageways that appear triangular when

diagonally viewing the weave. A thinner, smaller diameter weft wire is used;

these are driven very close together creating a very tight weave. Dutch weaves do not have a

straight-through, clear opening as do most plain weave styles. Instead the weave

style creates a tortuous path through which very fine filtration and particle

retention can be achieved. Dutch weaves may be specified by "mesh count" or

"absolute filter rating." |

| 4. Dutch Twill

Weave Similar to Plain Dutch except

woven in the Twill style with a double layer of weft wires. Each wire passes

over two wires then under two wires, still utilizing a smaller-diameter weft

wire, allowing an even tighter weave and even finer filtration than Plain Dutch

weave. There are no apertures in the true sense of the word as the filtrate

follows a sinuous path through the depth of the wire cloth. |

| 5. Reverse Dutch

Weave The same weave as Plain Dutch

except the warp and weft wires are reversed; I.E., the warp wires have a smaller

diameter than the weft wires. The larger weft wires are woven closer together

than would usually be seen in a Plain Dutch

weave. |